Topic: Life Cycle Engineering for Improving the Sustainability of Re-manufacturing

A Special Issue of Green Manufacturing Open

ISSN 2835-7590 (Online)

Submission deadline: 20 Feb 2025

Guest Editor(s)

Dr. Zhichao Liu

Department of Industrial and Management Systems Engineering, West Virginia University, Morgantown, WV, United States.

Dr. Tao Li

School of Mechanical Engineering, Dalian University of Technology, Dalian, Liaoning, China.

Special Issue Introduction

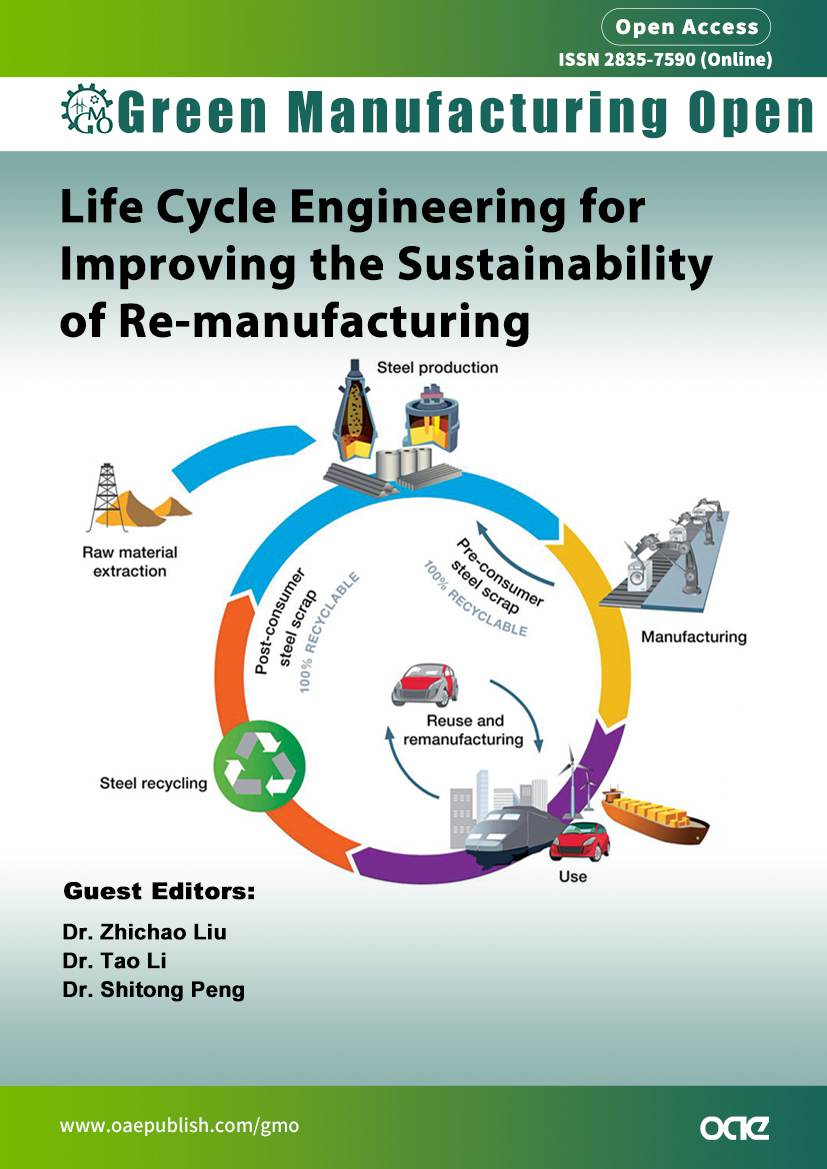

In the past decade, remanufacturing has been increasingly recognized as a critical element for realizing an efficient and sustainable manufacturing industry. It is a process whereby used/broken-down components - referred to as cores - are restored to like-new condition with an extended lifetime. Remanufacturing reclaims the material content and retains the embodied energy and labor used to manufacture the original component. Research shows that remanufacturing can reduce up to 80% of energy consumption and carbon dioxide emissions and 40%-65% of manufacturing costs compared to manufacturing a new part.

Despite the conventional wisdom that remanufacturing reduces environmental impacts, remanufacturing can lead to negative outcomes (e.g., consuming more energy). Thus, it is important to thoroughly investigate its environmental and economic impacts, understand the true impacts of remanufacturing decisions, and identify operating policies (e.g., robust scenarios) to ensure that remanufacturing is conducted when it is worth the effort.

Remanufacturing and its sustainability involve numerous aspects and disciplines, such as life cycle assessment (LCA), additive manufacturing technologies, mechanical engineering, and decision modeling and optimization. Successful development of sustainability-oriented engineering methodology will lead to a comprehensive understanding of the environmental/economic implications of Remanufacturing and provide effective decision support to reduce environmental/economic burdens at lower costs.

Keywords or key topics of the SI:

This Special Issue intends to bring together research articles highlighting the latest advancements in Remanufacturing, focusing on developing and deploying new analytical models, frameworks, optimization algorithms, and management strategies to improve the sustainability of Remanufacturing. Original research papers, review papers, industrial case studies, and short communications are welcomed to submit on themes such as, but not limited to:

● Modelling and optimization of energy consumption in Remanufacturing;

● Product/Process design for Remanufacturing;

● Advanced materials for Remanufacturing;

● Artificial intelligence and machine learning in Remanufacturing for product quality and process control;

● Life-cycle assessment: methods and case studies for Remanufacturing;

● Life-cycle costing: methods and case studies for Remanufacturing;

● Life-cycle sustainability assessment: methods and case studies for Remanufacturing;

● Life-cycle engineering of laser additive Remanufacturing;

● Proactive Remanufacturing.

Despite the conventional wisdom that remanufacturing reduces environmental impacts, remanufacturing can lead to negative outcomes (e.g., consuming more energy). Thus, it is important to thoroughly investigate its environmental and economic impacts, understand the true impacts of remanufacturing decisions, and identify operating policies (e.g., robust scenarios) to ensure that remanufacturing is conducted when it is worth the effort.

Remanufacturing and its sustainability involve numerous aspects and disciplines, such as life cycle assessment (LCA), additive manufacturing technologies, mechanical engineering, and decision modeling and optimization. Successful development of sustainability-oriented engineering methodology will lead to a comprehensive understanding of the environmental/economic implications of Remanufacturing and provide effective decision support to reduce environmental/economic burdens at lower costs.

Keywords or key topics of the SI:

This Special Issue intends to bring together research articles highlighting the latest advancements in Remanufacturing, focusing on developing and deploying new analytical models, frameworks, optimization algorithms, and management strategies to improve the sustainability of Remanufacturing. Original research papers, review papers, industrial case studies, and short communications are welcomed to submit on themes such as, but not limited to:

● Modelling and optimization of energy consumption in Remanufacturing;

● Product/Process design for Remanufacturing;

● Advanced materials for Remanufacturing;

● Artificial intelligence and machine learning in Remanufacturing for product quality and process control;

● Life-cycle assessment: methods and case studies for Remanufacturing;

● Life-cycle costing: methods and case studies for Remanufacturing;

● Life-cycle sustainability assessment: methods and case studies for Remanufacturing;

● Life-cycle engineering of laser additive Remanufacturing;

● Proactive Remanufacturing.

Submission Deadline

20 Feb 2025

Submission Information

Ten articles in the Special Issue are exempt from article processing charges.

For Author Instructions, please refer to https://www.oaepublish.com/gmo/author_instructions

For Online Submission, please login at https://oaemesas.com/login?JournalId=gmo&SpecialIssueId=GMO230307

Submission Deadline: 20 Feb 2025

Contacts: Lily Ji, Assistant Editor, gmo@oaemesas.com